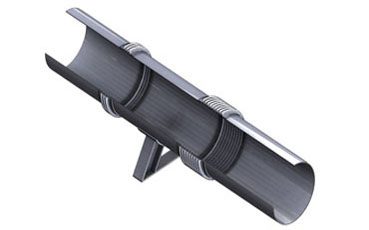

Single Expansion Joint

Read About Single Expansion Joint

Single expansion joint is simply a bellows element with end connections. A flexible element either with flange end or Butt Weld End to absorb any combination of three basic movements. I.e. Axial movement, Lateral deflection and Angular rotation along the axis of the pipe line. Metallic bellows are normally applied in the pipe line and Ducts where high temp & high pressure are present.These are basically to accommodate or absorb the thermal movements of the ducts or pipes due to high temperature and pressure.

YEC Single Expansion Bellows are specially designed to take care of these kind of movements and also capable to absorb duct or pipe misalignment in all three directions viz Axial, Lateral & Angular or combination of all three.

YEC has very unique range Single Expansion Joint.

It should be always remembered that thermal expansion can always occur in multi direction like Axial, Lateral & Angular.

Axial Bellows do not control the movement of the pipes and in case the piping analysis indicates that the expansion joint should accept axial compression, then in that case the piping must be guided and constrained so that only that movement occurs.

• Absorbs small amounts of axial, lateral, and angular movements

• Deflect in any direction

• Most economical

• Must be guided

• Requires main and directional anchors

• Size available – 15 NB to 4000 NB

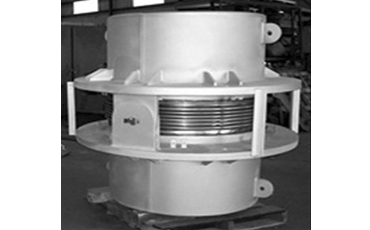

Double Expansion Joint

Read About Double Expansion Joint

This consists of two single joints joined by a common connector which is anchored to a rigid part of the structure by means of an anchor support base. YEC Double Expansion Joints are supplied with or without an anchor support base depending on the customer’s preference.

A double joint is used where the axial movement to be absorbed is too large to be handled by a single joint. The intermediate anchor on the center nipple divides this movement so that each bellows of the double joint absorbs its share of the movement. Double joints are usually located in the center of a pipe run so both ends are subjected to the same movements and have the same number of corrugations.

This figure typifies good practice in the use of a double expansion joint to absorb axial pipeline expansion. The intermediate anchor is conjunction with the two main anchors divides the pipeline into individual expanding sections so that there is only one expansion joint between any two anchors.

Size available – 15 NB to 4000 NB

Universal Expansion Joint

Read About Universal Expansion Joint

The movements occurred in two directions can only be absorbed by using Universal Expansion Joints. Universal expansion joints are made up of two bellows connected each other by an intermediate pipe and a system of tie rods able to withstand the thrust resulted of the internal pressure.

Movement Absorption

This type of expansion joints are used to absorb lateral movements in all planes. Also, with a special positioning of two tie rods at 180 degrees, the expansion joints becomes able to absorb some lateral and angular deflections at the same time.

The amount of lateral deflection depends on the convolution number of the bellows on each side of the expansion joint. This amount can also be increased by changing the length of the intermediate pipe. The tie rods are also effective to prevent possible torsion forces.

Advantages of Universal Tied Expansion Joints

• Absorption of lateral movements in all planes

• Easy to absorb large expansion movements

• Minimum application area

• Preventing axial inaccuracies increases the system safety

• Size available – 15 NB to 3500 NB

Elbow Pressure Balance Pipe Expansion Joint

Read About Elbow Pressure Balance Pipe Expansion Joint

This type of pipe expansion joint is really a combination of several types. Its purpose is to retain and balance the pressure thrust so that main anchoring of the pipe or adjacent equipment is not required, and forces and movements on attachment flanges of delicate equipment, such as turbines, are kept to acceptably low levels. The deflections to be accepted are handled by the proper type of pipe expansion joint, which normally, is a tied universal type to accept lateral movements. However, the pressure balanced elbow is usually required because axial deflections are also present. In order to accept these movements, a bellows is added beyond the elbow with the same cross-sectional area as the ones in the universal section. All of the lateral deflection is absorbed by the universal end, and there is no lateral deflection imposed on the balancing end. Therefore, the balancing bellows is almost always a single bellows type.

• Absorbs axial and lateral movements

• Eliminates main anchors

• Minimum guiding required

• Pressure forces remain in balance

• No volume change

• Size available – 25 NB to 3000 NB

Balance pressure thrust remains constant

Gimbals Type Expansion Joint

Read About Gimbals Type Expansion Joint

The Gimbal SS Bellow is basically same as the hinge type, except that instead of being limited to deflection in only one plane gimbal Expansion Joints are used to absorb angular rotation in any plane, using two pairs of hinges attached to a common floating gimbal ring. Gimbal systems generally consist of two gimbal expansion joints or two gimbal and one hinged expansion joint/bellow.

The advantages of this type of construction is it provides a close control over the movement imposed up on the bellows and also supports the dead weight of the pipe.

In addition, the wind and shear loads are also taken care of by the gimbal structure. Gimbal bellows are designed to absorb the full pressure thrust load of the expansion joint and thus guard the adjacent equipment from damage due to thrust loading.

• Absorbs angular rotation

• Eliminates pressure thrust forces

• Transmits shear and wind loads

• Supports dead weight

• Prevents torsion on bellows

• No main anchors required

• Minimum guiding required

• Low forces on piping system

• Size available – 25 NB to 3000 NB

Hinged Pipe Expansion Joint

Read About Hinged Pipe Expansion Joint

Hinged Pipe Expansion Joints contain hinges or pivots which allow the unit to bend in a single plane. These units are designed to restrict axial deflection, either in extension or compression. The hinge mechanism is typically designed to accept full pressure thrust. Also, because of the hinge mechanism’s design, shear loads, such as from the weight of adjacent piping, can be accepted by this pipe expansion joint, relieving the piping designer of having to provide additional supports and anchors required by the Single type.

Some hinge types can be provided with hinge pin holes which are slotted to permit limited axial travel. These “slotted hinge” types will not resist pressure thrust forces, and anchoring must be provided. This catalog only depicts the fully restrained hinged type. If axial travel is desired, the piping designer should clearly state that the slotted hinge type is wanted in the design requirements, and he should provide for pressure thrust anchoring. On the other hand, if the full axial restraint of the hinged type is desired, the piping designer should understand that there is no allowance in the expansion joint for any axial travel, including none for any installation misalignment.

- Angular motion in all planes

- Positive control over movement

- Eliminates pressure thrust forces

- Transmits external loads

- Bolsters dead weight

- Prevents torsion on bellows

- No main anchors required

- Minimum guiding required

- Low forces on piping system

- Most efficient in absorbing thermal deflections

- Size available – 25 NB to 3000 NB

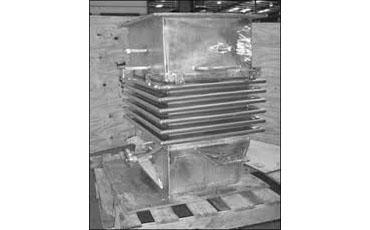

Rectangular Metallic Pipe Expansion Joint

Read About Rectangular Metallic Pipe Expansion Joint

Rectangular metal pipe expansion joints have a variety of applications in the power, petrochemical, refining, chemical, and steel industries. Since there are no standard duct sizes, and due to the wide range of pressure and temperature combinations, each rectangular metal pipe expansion joint is custom-engineered to provide the most economical design that will absorb the thermal movements of the system in which it is installed. Like circular pipe expansion joints, rectangular pipe expansion joints absorb three types of movement: axial, lateral and angular. For the purpose of designing rectangular bellows, it is critical to know in which direction the lateral and angular movements will occur, i.e. parallel to the long and/or short side of the bellows.

• Absorbs axial and lateral movements

• Variety of bellows geometry (for long straight sides)

• Normal guiding is required

• Manufactured for a wide variety of materials

• Size available – 100 NB to 4500 NB

Metal Hose Joint

Read About Metal Hose Joint

A Metal Hose is a flexible metal line element. There are two basic types of metal hose that differ in their design and application: strip wound hoses and corrugated hoses. Strip wound hoses have a high mechanical strength (e.g. tensile strength and tear strength). Corrugated hoses can withstand high pressure and provide maximum leak tightness on account of their material. Corrugated hoses also exhibit corrosion resistance and pressure tightness under the most extreme conditions, such as in aggressive seawater or at extreme temperatures such as found in space or when transporting cooled liquid gas. They are particularly well suited for conveying hot and cold substances.

With a history of more than one hundred years, metal hoses have given rise to other flexible line elements, including metal expansion joints, metal bellows and semi-flexible and flexible metal pipes.

Size available – 10 NB to 300 NB

Thick Wall Pipe Expansion Joint

Read About Thick Wall Pipe Expansion Joint

These may be a cost-effective option for large-diameter piping systems which operate at low pressure. Metals can be selected to satisfy different temperature conditions. The distribution of axial, angular, and lateral forces will be different when thick-wall pipe expansion joints are used. We can provide your design engineers with the potential forces and movements for proper design of the structural members supporting the system. These joints have a long life which justifies the initial investment.

Thick-wall expansion joints are used primarily in heat exchangers and large diameter piping systems where thin-wall expansion joints would not be sufficient. The bellows are typically fabricated from A516 Grade 70 material, with the thickness ranging from 3/16″ to 1″. Other materials are available to meet different temperature requirements.

• Size available – 100 NB to 3000 NB

Telescopic Expansion joint / Slide Sleeve type Expansion Joint

Read About Telescopic Expansion joint / Slide Sleeve type Expansion Joint

Telescopic Expansion Joint is a very compact and easy to install product, used for absorbing the expansion and contraction movements of a pipeline system. We are counted amongst the most preferred Telescopic expansion joint manufacturer. The product has been perfectly designed and developed for utmost customer satisfaction. We are also well equipped to cater the customer’s specific requirements. These Telescopic Expansion Joint are made out of high grade materials, sourced from reliable vendors, ensuring high quality, reliability, durability and versatility.

Features:

- Designed to counterbalance large movements at high pressures

- Rugged construction and ease of installation

- Excellent pressure and temperature range

Suitable for industrial oil & chemical piping, irrigation piping systems, sewage treatment, and more

- Size available – 25 NB to 3000 NB