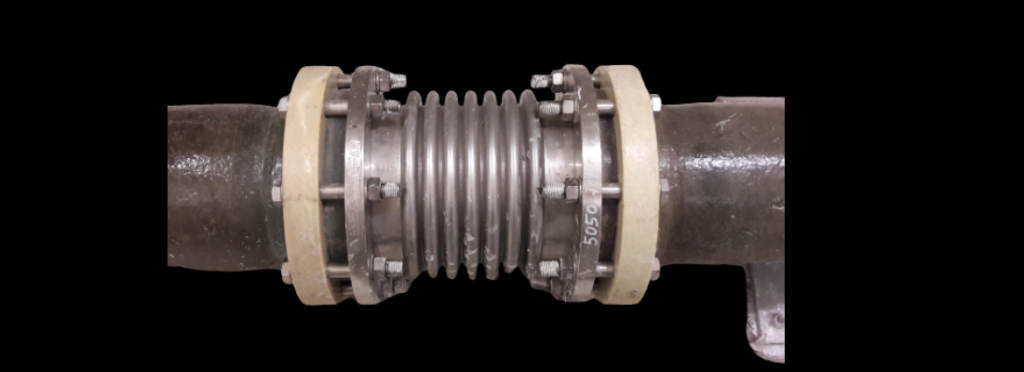

A Bellow Expansion Joint is a crucial component in various industrial applications, serving the purpose of accommodating movement, vibration, and thermal expansion in piping systems. These joints are designed to ensure the integrity of pipelines and equipment while extending their lifespan.

Bellow Expansion Joints are constructed with a series of convolutions or bellows, which are typically made from materials like stainless steel or other alloys, depending on the application’s specific requirements. These bellows can absorb axial, lateral, and angular movements, making them a versatile solution for various industries, including petrochemical, power generation, and manufacturing.

The primary function of a Bellow Expansion Joint is to prevent damage to pipes and equipment caused by thermal expansion and contraction. When pipes heat up or cool down, they expand and contract, potentially causing stress and damage to the entire system. Bellow Expansion Joints effectively absorb these movements, reducing stress on the piping and equipment, and preventing leaks or other issues.

Moreover, Bellow Expansion Joints help in dampening vibrations and noise generated by the fluid flowing through the pipelines, ensuring a safer and quieter working environment. In summary, a Bellow Expansion Joint is an indispensable component in various industrial settings.

Its ability to absorb movement, vibration, and thermal expansion not only prolongs the life of piping systems but also contributes to safer and more efficient operations. To ensure the optimal performance of your industrial equipment and piping systems, choosing the right Bellow Expansion Joint is essential.

So, if you’re looking to maintain the structural integrity and performance of your industrial systems, make sure to consider Bellow Expansion Joints, as they are a reliable solution for accommodating movement and thermal expansion, while also contributing to a quieter and safer work environment.

Bellow Expansion Joints in Piping Systems

Bellows expansion joints play a pivotal role in the functionality and durability of piping systems. Drawing from a decade of experience, I can emphasize their crucial importance. These ingenious components absorb thermal expansion, and vibrations, and compensate for misalignments, ensuring the structural integrity of pipelines in a myriad of industries.

Crafted with precision, bellows expansion joints can withstand extreme temperatures and harsh chemical environments. By providing flexibility in multiple directions, they facilitate movement while preserving the system’s integrity.

Industries ranging from petrochemicals to power generation have come to rely on these components, recognizing their pivotal role in enhancing safety, reducing maintenance costs, and minimizing downtime. Their impact on optimizing critical system performance is indisputable.

Types of Bellows & Expansion Joints

Metallic Expansion Joints

Metallic expansion joints are essential components in piping systems, and as an experienced content writer with a decade of expertise, I can elaborate on their significance. These joints are meticulously engineered to absorb thermal expansion, vibrations, and movements within pipelines.

Crafted from various metals, including stainless steel and other alloys, they offer exceptional durability and corrosion resistance. These joints are widely used in industries such as petrochemicals, power generation, and HVAC systems, where temperature fluctuations and structural shifts are common.

Properly designed and installed metallic expansion joints extend the lifespan of pipelines, prevent leakages, and enhance the overall efficiency and safety of industrial systems. Their role in maintaining the integrity of critical infrastructure cannot be overstated.

Rubber Expansion Joints

Rubber expansion joints are integral components in piping systems, known for their flexibility and ability to absorb movements, vibrations, and sound. Comprising layers of rubber or elastomeric materials, these joints provide essential cushioning to accommodate thermal expansion and contraction, as well as structural shifts in pipelines.

They are commonly used in industries like HVAC, water treatment, and chemical processing, where noise reduction and vibration isolation are crucial. Rubber expansion joints help to extend the longevity of piping systems, reduce maintenance costs, and enhance overall safety.

Their versatility, cost-effectiveness, and ease of installation make them a preferred choice for engineers and contractors working on various industrial applications.

Single Expansion Joint

In the realm of piping systems, single expansion joints are indispensable components designed to tackle the challenge of axial movement. These joints are singular bellows-shaped elements strategically placed to absorb and accommodate thermal expansion and contraction in a pipeline.

By compressing or extending along a single axis, they effectively minimize the stress on the piping system. Single expansion joints are known for their cost-effectiveness and relatively straightforward installation, which make them a preferred choice in various applications.

They serve as a fundamental solution when the primary requirement is accommodating movement in one direction while preserving the structural integrity of the pipeline. Their reliability and versatility contribute significantly to ensuring the seamless operation of piping systems across different industries.

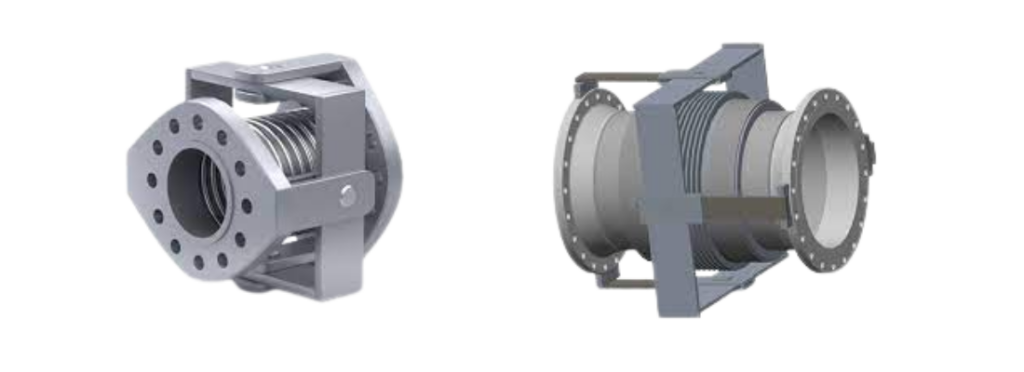

Universal Expansion Joint

Universal expansion joints are pivotal components in the realm of piping systems, engineered to address complex challenges posed by multi-directional movement. These joints offer exceptional flexibility and can absorb axial, lateral, and angular movements simultaneously.

Their unique design features two bellows joined by a center pipe and accommodates movement in multiple directions. They play a critical role in minimizing stress and vibration in pipelines, promoting their longevity and structural integrity.

Universal expansion joints are favored for their adaptability in a wide range of applications, ensuring the seamless functioning of piping systems across various industries.

Hinged Expansion Joint

Hinged expansion joints are engineered to provide a specific pivot point for controlled movement in piping systems. These joints excel in accommodating angular deflection while restraining axial and lateral movements.

The pivotal hinge design allows for rotation around a central axis, offering a precise solution for applications where angular movement is critical. These joints play a crucial role in directing forces and ensuring the stability of pipelines in challenging environments.

They are widely utilized in industries where precise alignment and controlled movement are essential, making hinged expansion joints an indispensable component in various piping systems.

Gimbaled Expansion Joint

Gimbaled expansion joints are the epitome of flexibility and stability in piping systems. These ingenious components enable multidirectional movement, making them ideal for applications where complex movements and stress relief are essential.

Their design allows for angular movement in multiple planes, ensuring that pipelines can bend, twist, and pivot without transmitting excessive stress to the system. This versatility is especially valuable in industries with dynamic conditions, where temperature fluctuations, vibrations, or external forces can impact pipeline integrity.

By providing unhindered movement while maintaining structural integrity, gimbaled expansion joints play a pivotal role in preserving the longevity and reliability of piping systems.

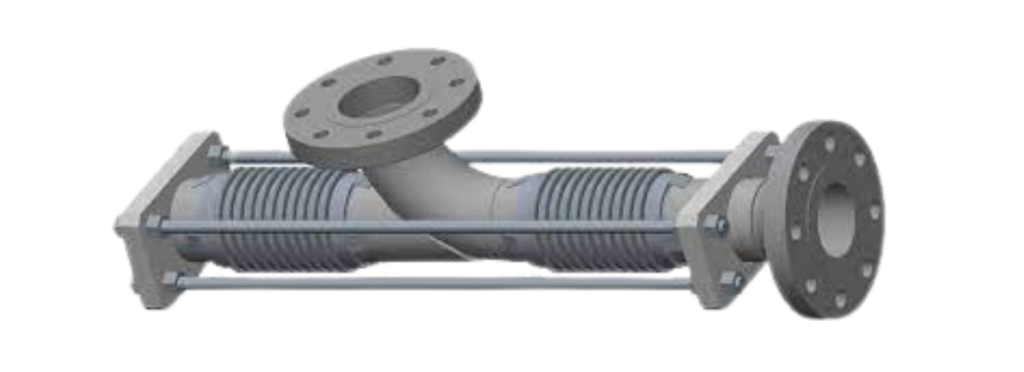

Pressure Balanced Expansion Joint

Pressure-balanced expansion joints are engineering marvels designed to tackle the challenging demands of high-pressure piping systems. These joints adeptly absorb axial movement while maintaining a balance between pressure thrust and restoring force.

This balance is achieved through the use of bellows and balancing pistons, which work together to counteract the imposed loads.

In applications where pressure differentials are substantial, pressure-balanced expansion joints are indispensable.

They offer protection against the forces that can otherwise compromise the integrity of a piping system. By ensuring equilibrium between the internal and external pressures, these expansion joints contribute to the safety, efficiency, and durability of complex piping networks.

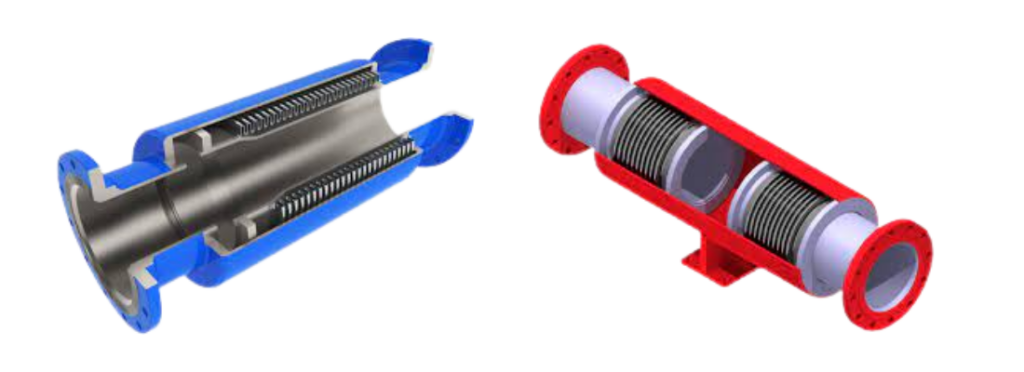

Externally Pressurized Expansion Joint

Externally pressurized expansion joints are indispensable components in the world of high-pressure systems. They excel in absorbing axial movement and dealing with substantial internal pressures. These expansion joints comprise metal bellows, which are protected by an outer shell.

The clever design allows the internal pressure to push against the outer shell, which counteracts the forces acting on the bellows. In applications with extreme pressure differentials, externally pressurized expansion joints come to the rescue, ensuring the integrity of the piping system.

They effectively handle the challenges posed by high-pressure environments, contributing to the safety and longevity of critical industrial infrastructure.

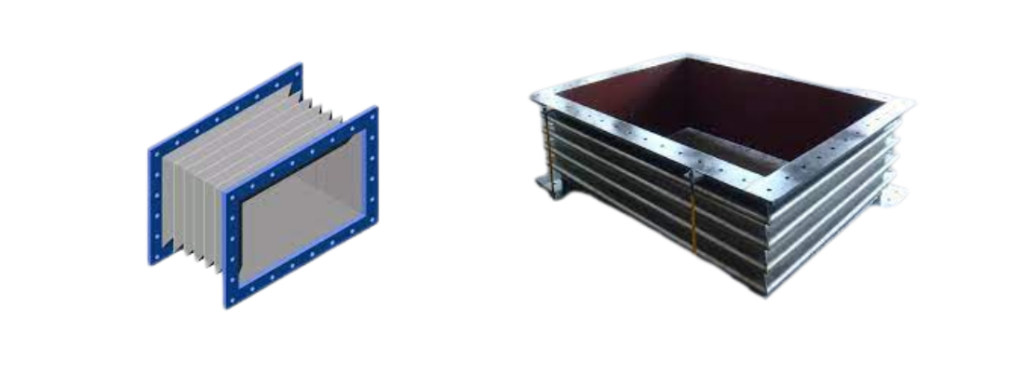

Rectangular Expansion Joint

Rectangular expansion joints are custom-engineered solutions, designed to accommodate non-standard applications where circular or round expansion joints might not be the right fit.

These expansion joints are typically used in ductwork and rectangular or square-shaped systems, where they play a pivotal role in compensating for thermal expansion, contraction, and misalignment.

Their adaptability to different configurations makes them ideal for a range of industries, including HVAC, power generation, and industrial processes.

Rectangular expansion joints ensure the integrity of the system, prevent leakage, and maintain the efficient operation of rectangular ducts and pipelines. Their tailor-made design allows them to seamlessly fit into unconventional spaces, meeting the specific needs of complex systems.

Thick Wall Expansion Joint

Thick wall expansion joints are specialized components designed to withstand extreme conditions and offer unparalleled durability. These joints are characterized by their heavy-duty construction, with thicker walls that can endure high pressures, elevated temperatures, and aggressive media.

They play a crucial role in various industries, including chemical processing, power generation, and oil and gas. Their robust design ensures the containment of corrosive substances and prevents leakages, contributing to system safety and integrity.

Thick wall expansion joints are tailored to withstand the most demanding environments, making them a trusted choice for critical applications where reliability is paramount. Their resilience and longevity make them an essential component in industries that demand uncompromising performance.

Stainless Steel Expansion Joints

Stainless steel expansion joints are the go-to choice for critical applications in industries that demand resilience, durability, and corrosion resistance. Their exceptional properties make them indispensable for a wide range of industrial processes.

The primary reason for choosing stainless steel expansion joints is their ability to withstand harsh environments, including exposure to aggressive chemicals and extreme temperatures. They provide a reliable solution to compensate for thermal expansion, vibration, and movement in piping systems, preventing structural damage and leakages.

Stainless steel’s corrosion resistance ensures a longer service life, reducing maintenance and replacement costs. Additionally, they maintain their integrity under high pressure, making them suitable for applications in the chemical, petrochemical, and energy sectors.

Whether it’s mitigating stresses in pipelines or accommodating movement in complex machinery, stainless steel expansion joints excel in maintaining system integrity, thus ensuring safe and efficient operations. When it comes to critical applications, stainless steel expansion joints are the ultimate choice for reliability and longevity.

What is the difference between a bellows and an expansion joint?

Design and Construction:

Bellows: A bellows is typically a single, convoluted (folded) section made from thin-walled metal. It is designed to compress and extend along its length.

Expansion Joint: An expansion joint is more complex and versatile. It can consist of multiple bellows, and it often includes additional components such as flanges, liners, and tie rods.

Movement Capability:

Bellows: Bellows primarily accommodate axial (longitudinal) movement, such as expansion and contraction due to temperature changes.

Expansion Joint: An expansion joint can handle various types of movement, including axial, lateral (transverse), angular, and even torsional movement. This makes it suitable for a wider range of applications.

Types and Styles:

Bellows: Bellows are usually limited to one style – the single convolution design.

Expansion Joint: Expansion joints come in various styles, including single, universal, hinged, gimbaled, pressure-balanced, and more, each tailored to specific movement requirements.

Applications:

Bellows: Bellows are often used for simpler applications, where primarily axial expansion and contraction are expected.

Expansion Joint: Expansion joints are employed in more complex scenarios where multiple types of movement need to be accommodated.

Bellows Expansion Joins Benefits

Bellows expansion joints offer several key benefits in piping and ducting systems, making them a valuable component for various industrial applications. These benefits include:

- Flexibility: Bellows provide the flexibility needed to absorb movements caused by thermal expansion, vibrations, and other dynamic forces. This flexibility helps prevent damage to the system and ensures its longevity.

- Stress Reduction: By absorbing movement and stress, bellows reduce the risk of damage to surrounding components, such as pipes, valves, and equipment. This can lead to cost savings through reduced maintenance and repairs.

- Noise and Vibration Control: Bellows help dampen noise and vibration, improving the safety and comfort of the work environment while minimizing the risk of fatigue failures in the system.

- Corrosion Resistance: Bellows can be manufactured from corrosion-resistant materials, extending the lifespan of the expansion joint and reducing the risk of contamination in sensitive processes.

- Customization: Bellows expansion joints can be tailored to meet specific application requirements, including size, material, and movement capabilities, ensuring a precise fit for each system.

- Improved Flow: Bellows can also be designed to maintain the integrity of fluid or gas flow within the system, ensuring efficient operation.

Why choose Yogiraj Engineering Company for bellows and an expansion joint

Yogiraj Engineering Company stands out as the ideal choice for all your bellows and expansion joint needs for several compelling reasons:

- Expertise and Experience: With years of experience in the industry, we have honed our expertise in the design and manufacturing of bellows and expansion joints. Our team comprises skilled professionals who understand the complexities of different applications.

- Custom Solutions: We recognize that each project is unique, and our commitment to delivering tailored solutions sets us apart. We work closely with clients to design and produce bellows and expansion joints that precisely meet their requirements.

- Quality Assurance: Quality is non-negotiable at Yogiraj Engineering Company. Our products undergo rigorous testing to ensure they meet the highest industry standards. This dedication to quality guarantees the longevity and reliability of our products.

- Prompt Delivery: We understand the importance of timely delivery for your projects. Our streamlined processes and efficient production allow us to deliver your bellows and expansion joints promptly.

- Competitive Pricing: We offer competitive pricing without compromising on quality. We aim to provide cost-effective solutions that align with your budget.

- Excellent Customer Support: Our customer-centric approach ensures that you receive exceptional support at every stage, from product selection to after-sales service.

- Wide Application Range: Our bellows and expansion joints find utility across various industries, including petrochemical, power generation, HVAC, and more.

FAQ’s – 10

What are bellows expansion joints, and why are they important in piping systems?

Bellows expansion joints are flexible components used in piping systems to absorb movements, such as thermal expansion and vibrations. They help prevent damage to the system and ensure its longevity.

How do metallic expansion joints differ from rubber expansion joints?

Metallic expansion joints are made of metals like stainless steel and are used in high-temperature and high-pressure applications. Rubber expansion joints are constructed with elastomeric materials and are favored for their flexibility and noise reduction capabilities.

What is the role of single expansion joints in piping systems?

Single expansion joints primarily accommodate axial movements, such as expansion and contraction due to temperature changes. They are known for their cost-effectiveness and straightforward installation.

Why are universal expansion joints essential in piping systems?

Universal expansion joints are crucial because they can handle complex multi-directional movements, including axial, lateral, and angular shifts simultaneously. This versatility ensures the longevity and structural integrity of pipelines.

How do hinged expansion joints differ from other expansion joints?

Hinged expansion joints provide a specific pivot point for controlled angular movement while restraining axial and lateral movements. They are used in applications where precise alignment and controlled movement are essential.

What are the key benefits of gimbaled expansion joints?

Gimbaled expansion joints offer flexibility and stability, allowing for multidirectional movement. They are ideal for applications where complex movements and stress relief are essential.

Why are pressure balanced expansion joints crucial in high-pressure piping systems?

Pressure-balanced expansion joints are designed to absorb axial movement while maintaining a balance between pressure thrust and restoring force. They are indispensable in applications with substantial pressure differentials.

How do externally pressurized expansion joints handle high-pressure environments?

Externally pressurized expansion joints absorb axial movement and cope with substantial internal pressures by using metal bellows protected by an outer shell.

What are the unique applications of rectangular expansion joints?

Rectangular expansion joints are used in ductwork and rectangular or square-shaped systems, where they compensate for thermal expansion, contraction, and misalignment.

What makes thick wall expansion joints suitable for extreme conditions?

Thick wall expansion joints are designed to withstand high pressures, elevated temperatures, and aggressive media. They are robust and ensure the containment of corrosive substances, contributing to system safety and integrity.